Optical manufacturing and metrology division

For information about polishing of Modest-sized Aspherics click here.

Large Optics - Facilities

The OSL Large Optics Facility hosts the former Grubb Parsons 1m capacity polishing machine, and 2.5m polishing and diamond milling machine. The latter machine has been upgraded by OSL with computer controlled milling for producing spherical, aspheric and flat surfaces, and edging and beveling.

| |

| The 2.5m Polishing machine |

A suite of large test optics, originating in Grubb Parsons but acquired by courtesy of Durham University, provides a unique test facility. Included are large reference flats and spheres, plus specialized meniscus lenses up to 1.5m diameter for the modified-Hindle test of convex telescope secondary mirrors.

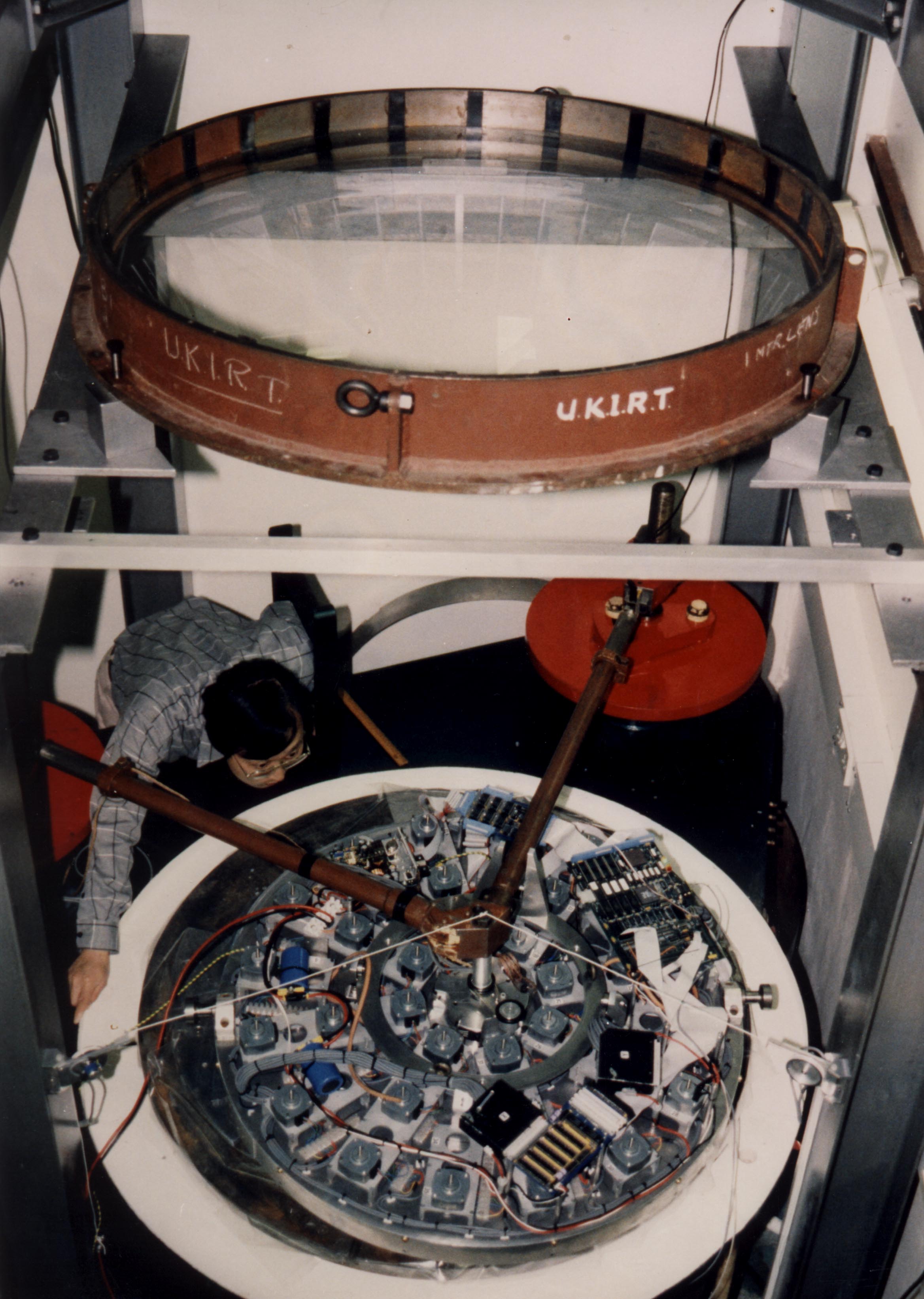

Large Optics - Active Lap

As part of the UK's national effort to develop technologies relevant to 8m telescopes, an 85cm diameter computer-controlled polishing tool has been co nstructed with PPARC support.

|

|

|

| The active Lap |

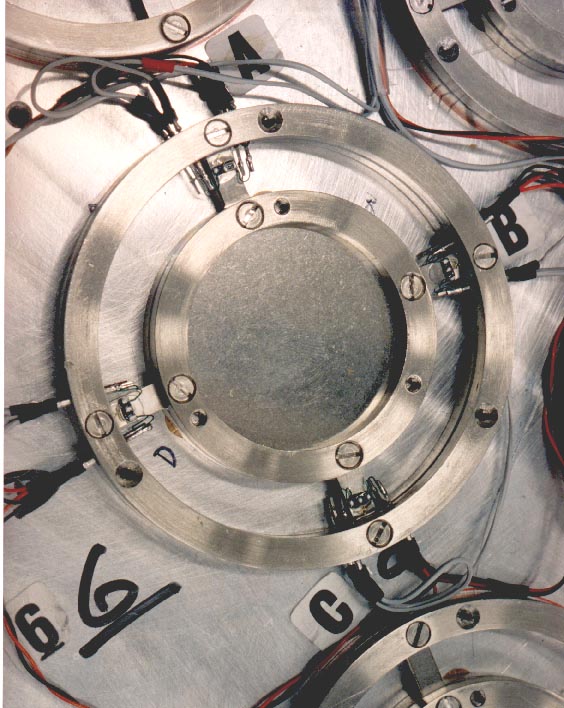

Load cell |

This incorporates a flexible membrane, an array of force actuators, and an array of load cells custom-designed in-house (to sense the distribution of polishing forces in real-time). The tool was used experimentally for working an 85cm diameter scale model of the proposed (but since deferred) 2.5m diameter wide-field convex hyprboloid secondary for Gemini. The demonstration of this technology provided the key concept that led to the simplified and rugged small-size tooling that underlies the industrialized computer controlled machine being brought to market by OSL's spin-off company ZEEKO. OSL plans to replace the active lap (which would have to be re-built for each job) with a scaled-up version of the OGL small-tool polisher (which is general in applicability).

Large Optics - Metal Mirrors

The current emphasis of research is on high-quality but inexpensive metal optics, particularly nickel-coated aluminium mirrors. With the optimum choice of materials, coating and processing, these can have significant advantages compared with classical glass and zero-expansion mirrors. A 1.8m diameter metal mirror has been successfully completed and delivered to the Birr Foundation, Ireland.

| |

| The Birr aluminium mirror |

The next major application is for adaptive secondary mirrors for ground-based telescopes. In the longer term, metal mirrors may present significant advantages for the segmented mirrors of the next generation of extremely large (50 to 100m) telescopes. However, other applications including space, are being promoted.